AUTOMATISON

The word “automation“ is derived from the Greek autómatos which means “to act independently”.

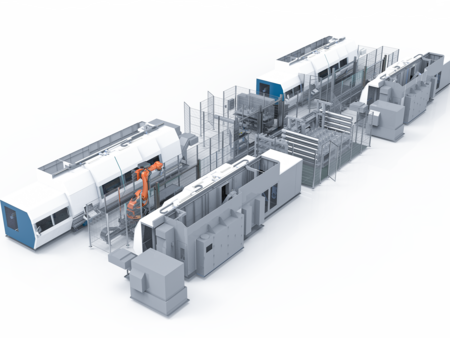

Depending on the customer's requirements, different automation solutions are used for automatic loading and unloading of workpieces. The offer ranges from gantry loaders to articulated robots. Peripheral transport and storage systems for workpieces, tools and jaws can be combined as desired.

YOUR ADVANTAGES

- 24/7 production with minimal operating effort

- Suitable for small batch sizes

- Ideal for repeat orders

- Customer-specific options such as outward transfer of samples, inscribing, cleaning, raw part measuring, etc.

- Additional machining using robots (e.g. deburring)

- Camera-based recognition system

- Data exchange via Profibus or OPC-UA

ENGINEERING MARVEL

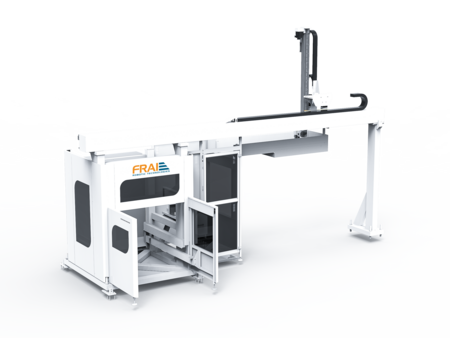

SPACE-SAVING ACCESS GENIUS

The use of gantry robots is one of the most efficient automation solutions for production processes. Modular gantry loaders are loading the machine from the top and therefore grant free access to the machine without requiring much space. The modularity related to the loader’s design not only creates large travels and work spaces, but also masters huge loads.

The reduced space requirement is a major advantage in small production areas and regarding retrofit of automation solutions.

FLEXIBLE MOVEMENT GENIUS

The three-dimensional kinematics of industry robots facilitate the use of end effectors (e.g. grippers).

No matter if limited access to the machine, complex motion sequences, short cycle times or other additional tasks (deburring, cleaning, orientation, turning, etc.) – the articulated robot will find its way. Thanks to their mobility, articulated robots are versatile handling systems for assembly, handling and machining tasks.

PRODUCTION ALLROUNDER

Thanks to the three-dimensional kinematics of the industrial robot, guiding end effectors (e.g. grippers) is easy.

Regardless of whether there is limited access to the machine, complex motion sequences, short cycle times or other additional tasks (deburring, cleaning, orienting, turning, etc.), the jointed-arm robot finds its way. This mobility makes the jointed-arm robot a universally applicable handling system for assembly, handling and machining tasks.

FUTURE OF AUTOMATION

Mobile robots move around completely autonomously with no need for cables or human input for them to work. Another key advantage of mobile robots is that they avoid obstacles, meaning that they can be used in halls where the set-up is constantly changing and where machines and people are moving around. Sensors help to ensure that mobile robots move safely and efficiently between locations and work safely and efficiently with people, forklifts and other material handling equipment.