ENGINEERING MARVEL

SPACE-SAVING ACCESS GENIUS

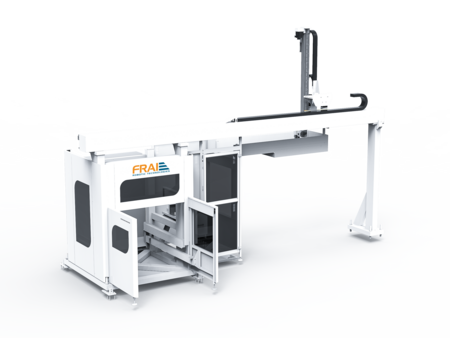

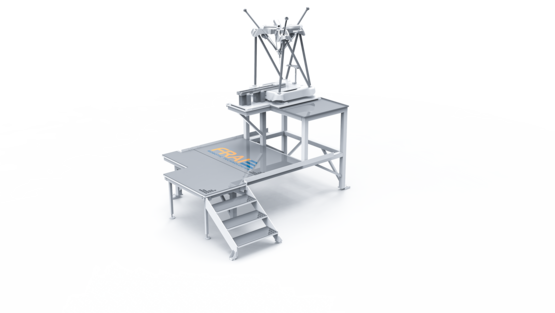

The use of gantry robots is one of the most efficient automation solutions for production processes. Modular gantry loaders are loading the machine from the top and therefore grant free access to the machine without requiring much space. The modularity related to the loader’s design not only creates large travels and work spaces, but also masters huge loads.

The reduced space requirement is a major advantage in small production areas and regarding retrofit of automation solutions.

FLEXIBLE MOVEMENT GENIUS

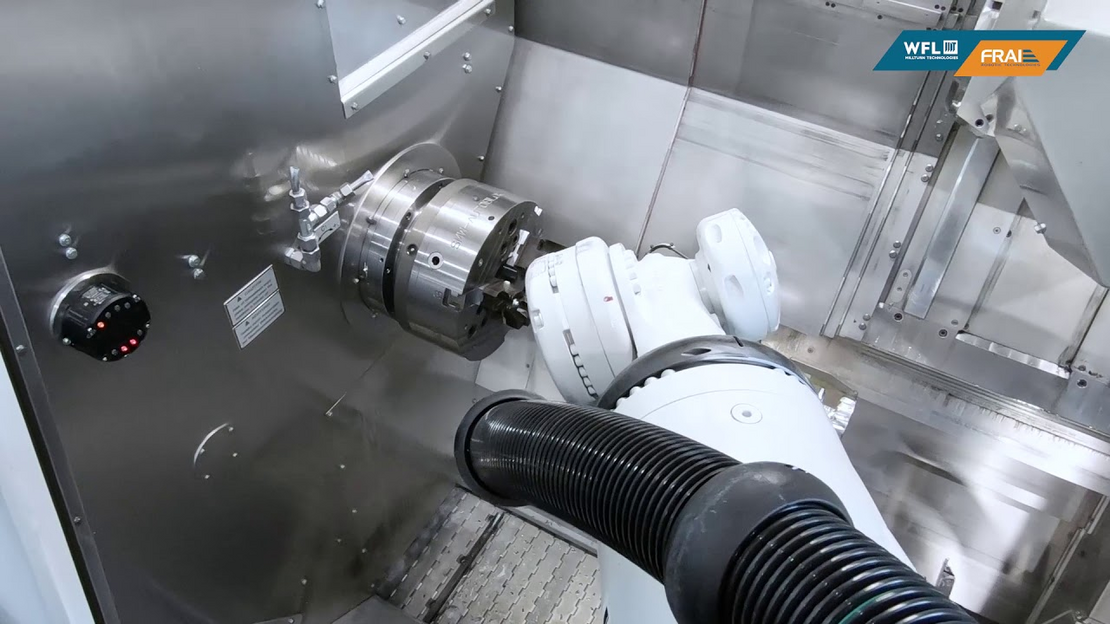

The three-dimensional kinematics of industry robots facilitate the use of end effectors (e.g. grippers).

No matter if limited access to the machine, complex motion sequences, short cycle times or other additional tasks (deburring, cleaning, orientation, turning, etc.) – the articulated robot will find its way. Thanks to their mobility, articulated robots are versatile handling systems for assembly, handling and machining tasks.

PRODUCTION ALLROUNDER

Thanks to the three-dimensional kinematics of the industrial robot, guiding end effectors (e.g. grippers) is easy.

Regardless of whether there is limited access to the machine, complex motion sequences, short cycle times or other additional tasks (deburring, cleaning, orienting, turning, etc.), the jointed-arm robot finds its way. This mobility makes the jointed-arm robot a universally applicable handling system for assembly, handling and machining tasks.

FUTURE OF AUTOMATION

Mobile robots move around completely autonomously with no need for cables or human input for them to work. Another key advantage of mobile robots is that they avoid obstacles, meaning that they can be used in halls where the set-up is constantly changing and where machines and people are moving around. Sensors help to ensure that mobile robots move safely and efficiently between locations and work safely and efficiently with people, forklifts and other material handling equipment.

successful projects

dedicated employees

years of experience

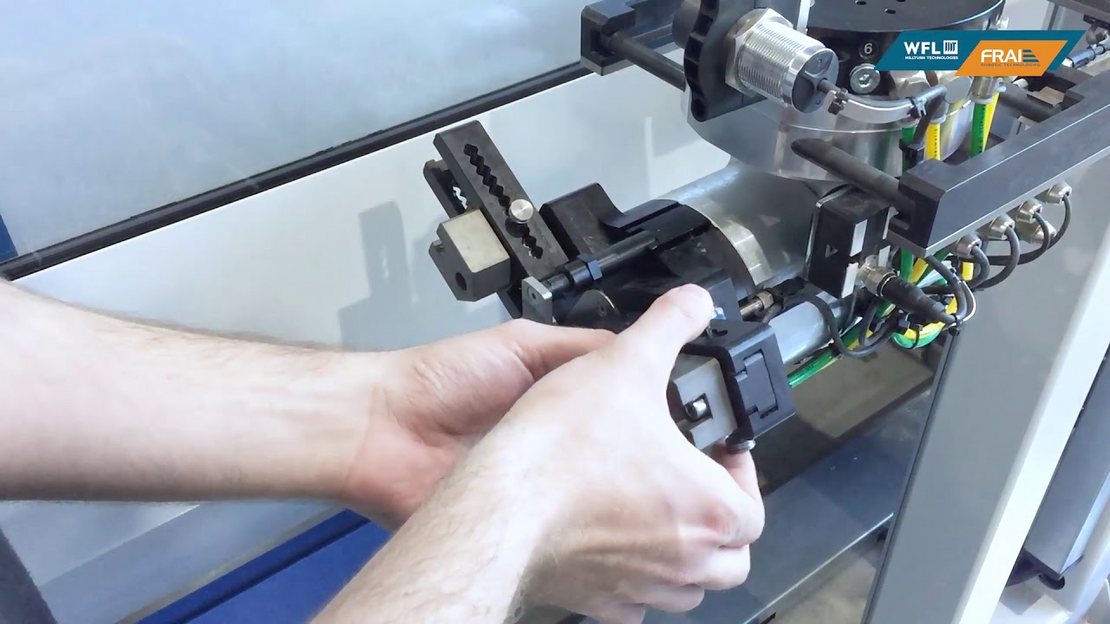

Changing the gripper in a robotic cell

Infeed & outfeed at the SPC drawer

Manual insertion of workpieces

Automatic insertion & transfer of the workpiece

On-the-fly measurement using robot technology in the M30-G MILLTURN

Quick jaw adjustment system in a M30-G MILLTURN

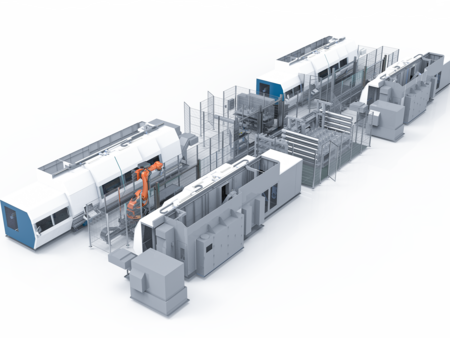

Customized Turnkey Solutions make the difference

FRAI FACINATES BY PUSHING THE BOUNDARIES OF AUTOMATION

“Very good and reliable cooperation and on-time delivery. We are looking forward to further collaborations.”

Mechanical Engineer

THE VERSATILE WORLD OF AUTOMATION

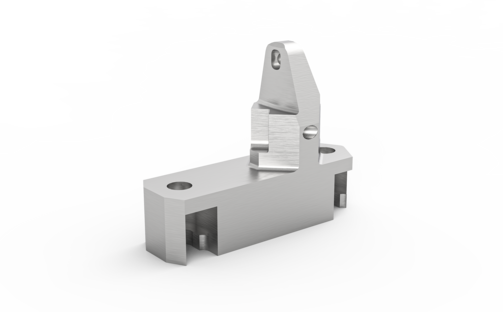

KEEP A THIGHT GRIP

Robot and workpiece are connected by means of a gripping process which forms the essential basic motion for grasping and holding.

- 2 jaw grippers

- 3 jaw grippers

- Yoke gripper

- Magnetic grippers

- Change system

SAVE AND COMPACT STORRAGE

The right workpiece storage not only allows for a safe and correct supply of raw parts, but also for the storage of machined parts. This ultimately leads to an increase in productivity.

- Rotary magazine

- Conveyor belts

- Shaft magazine belts

- Level storages

- Stacking cells

LEND A HAND

Additional stations not only offer the possibility of creating added value, but also support employees by taking on possible additional tasks.

- Dot peen marking

- Alignment

- Cleaning

- Integration of measuring station

- Turning

THE FLEXIBLE WAY OF CONTRACT MANUFACTURING

THE ONE-STOP SERVICE

FRAI’s team consists of experts dealing with the development and construction of highly complex automation solutions. This is of considerable benefit to contract manufacturing as well. The company focuses on small batch production and has an extensive machinery with 15 manufacturing machines. For this reason, FRAI’s qualified manufacturing team can respond to their customer’s individual requirements.