GRIPPER SYSTEMS

The gripper system is the connection between robot and workpiece. It is therefore an important element which has considerable influence on the flexibility, reliability and quality of the workpiece transfer. There are not only different versions of automation solutions, but also various gripper systems. Both offer several possibilities regarding implementation and application. The design of the gripper system as well as the gripper elements are subject to many different factors. Which one to choose depends on the range of workpieces, the space available in the transfer area and the requirements concerning accuracy in transfer.

Automation is always about reducing unit costs. For this reason, the economic aspect of the production has to be considered already during the project phase. Short workpiece changing times and low investment costs are required. FRAI’s employees know best whether to opt for a single gripper, a double gripper or a multi-gripper in order reduce the changing time for parts.

Quick-change couplings allow for a rapid change of grippers. This is especially important when using grippers which cannot handle the full range of parts. The changing process can be carried out manually or automatically. Under certain conditions, this allows for implementing self-equipping systems and results in an efficient production of small batch sizes – even for an extensive range of parts.

The quality of the transfer as well as the required part changing time are crucial factors when choosing a gripper, since this decision forms the very basis for consistent quality in production. This is why FRAI’s experts pay special attention to the following aspects:

- suitable pressing elements

- suitable joining modules

- intelligent software modules

- suitable design of gripper jaws

- arrangement of grippers

- presence of monitoring elements

FRAI Robotic Technologies relies on their experience and state-of-the-art technology. The team can count on in-house gripper solutions as well as purchased grippers both in combination with additional modules and solutions from many different implemented projects. Working with FRAI’s design engineers means developing the best solution for your system together.

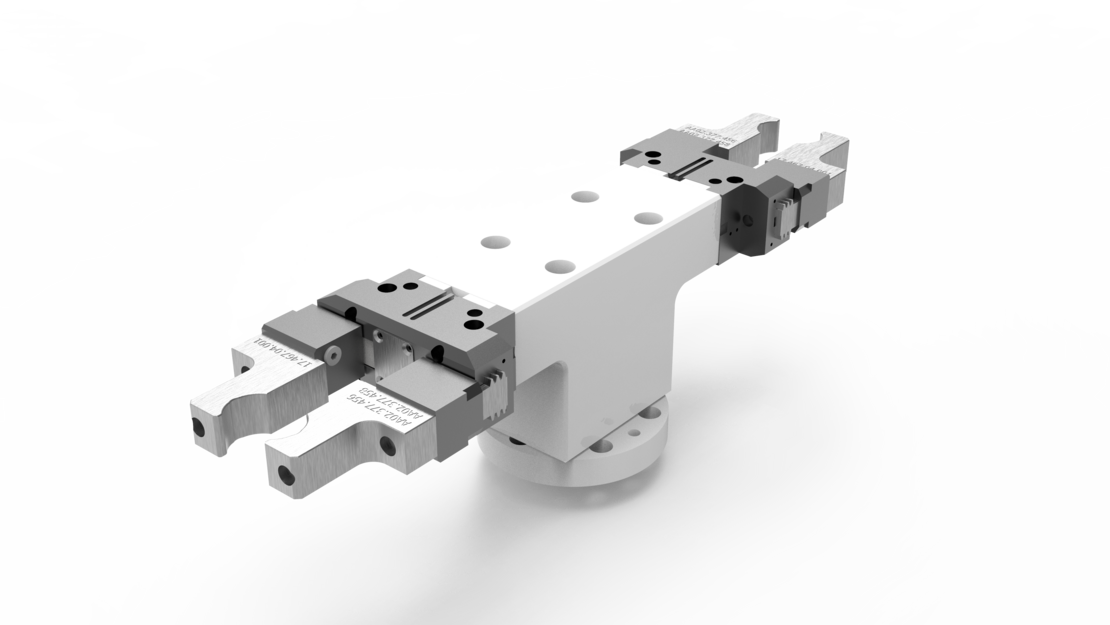

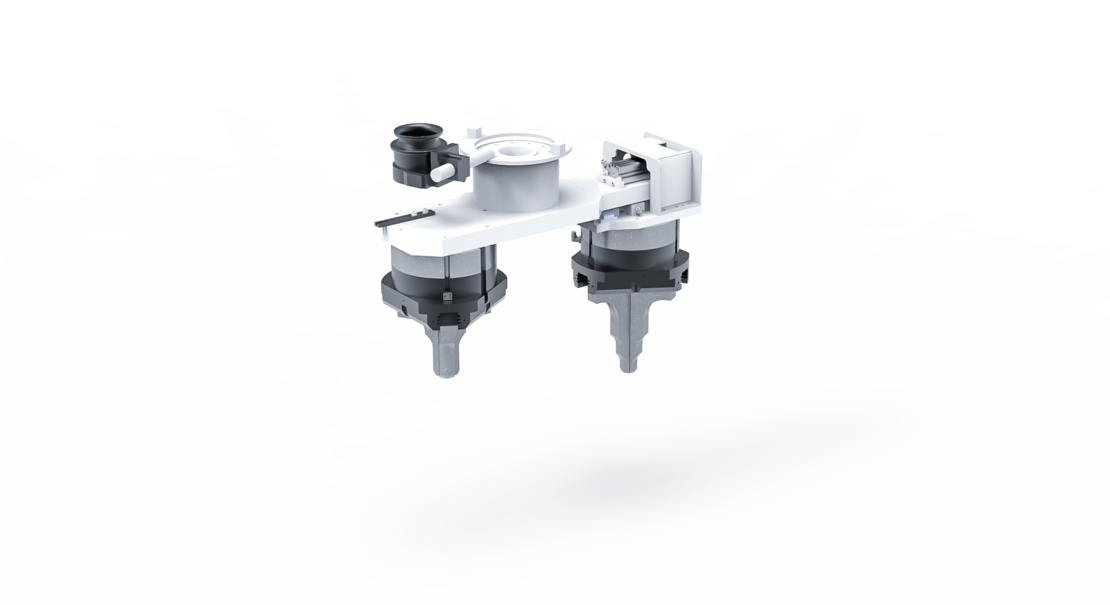

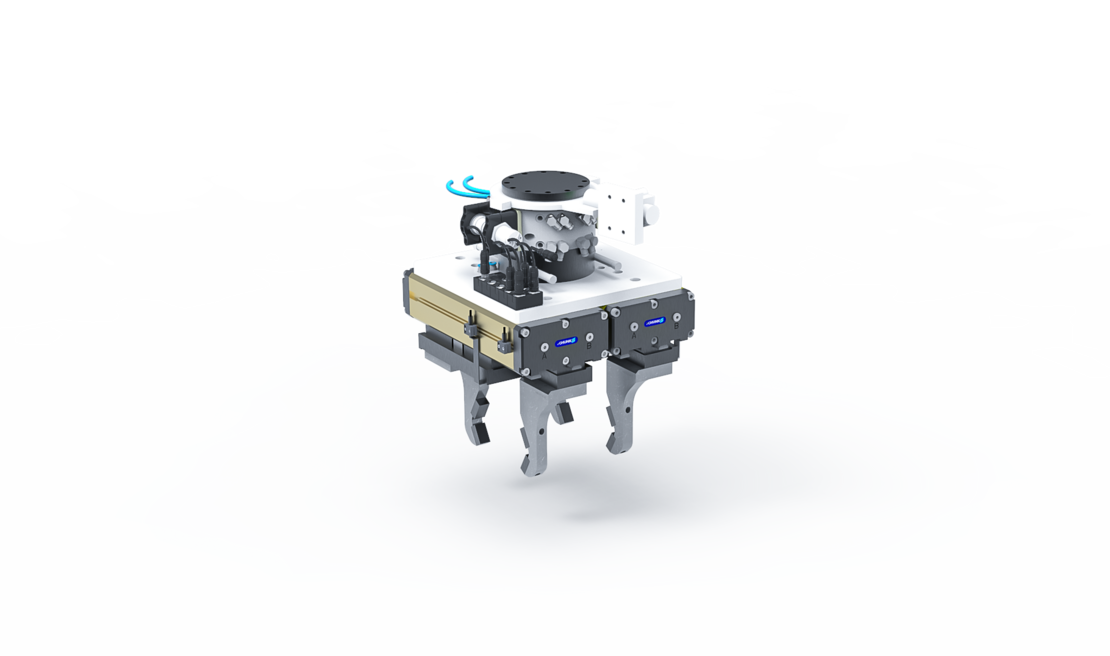

Double parallel gripper

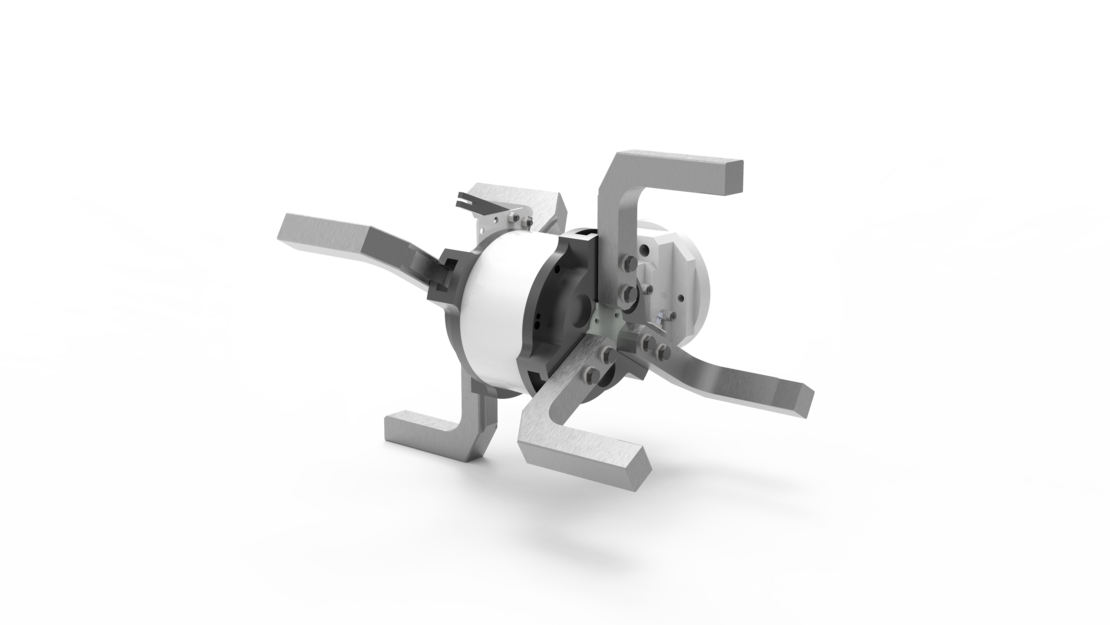

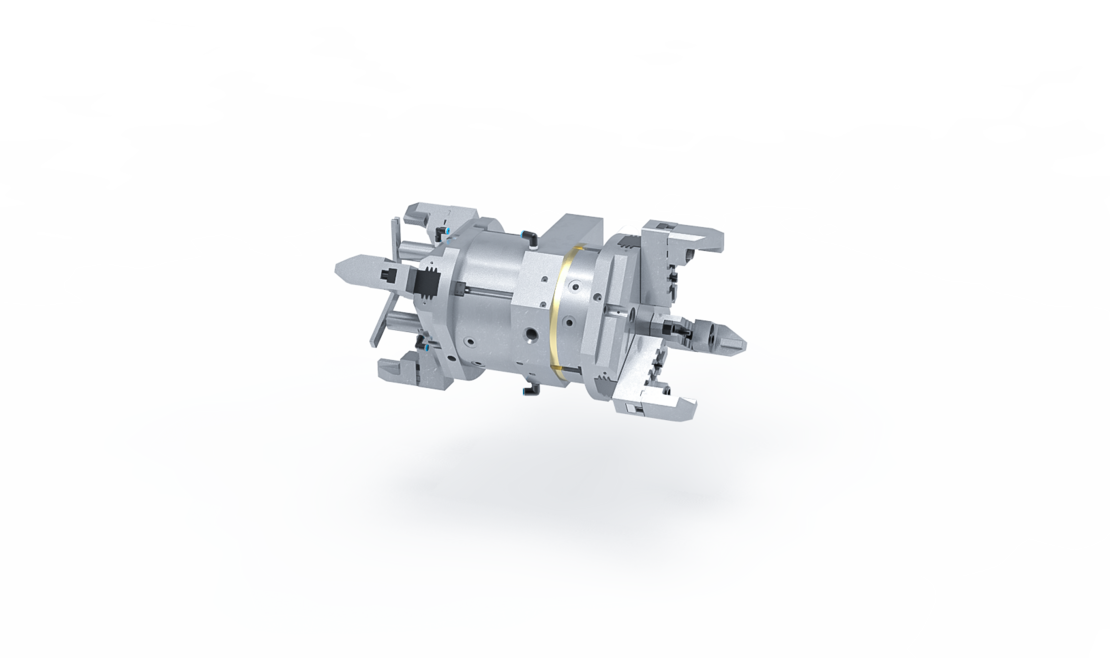

Double centric gripper

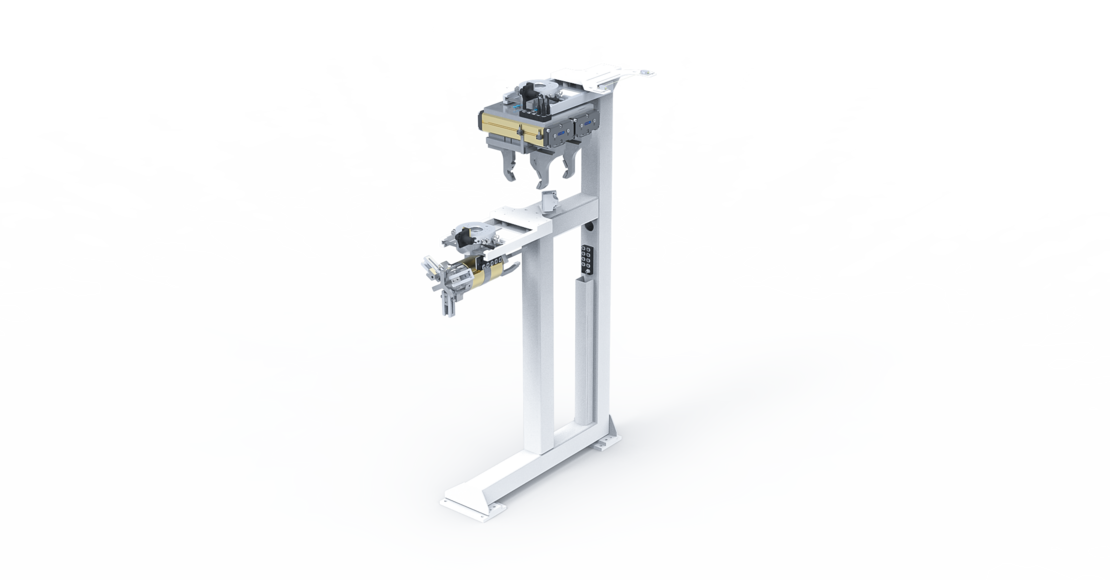

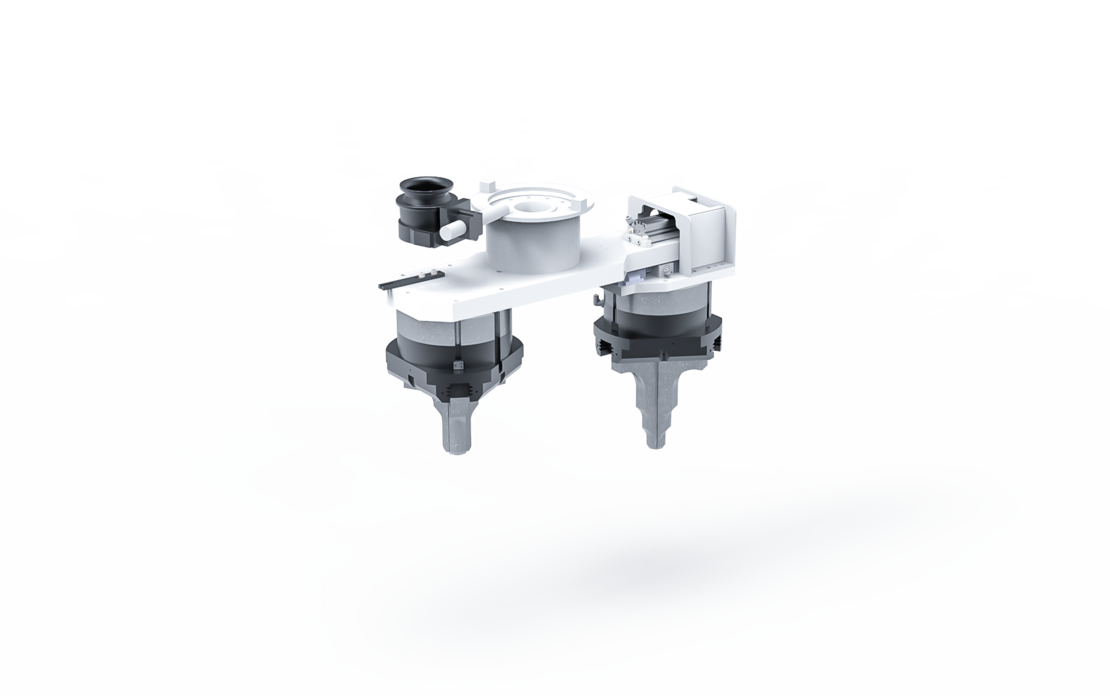

Dual gripper storage for gripper change

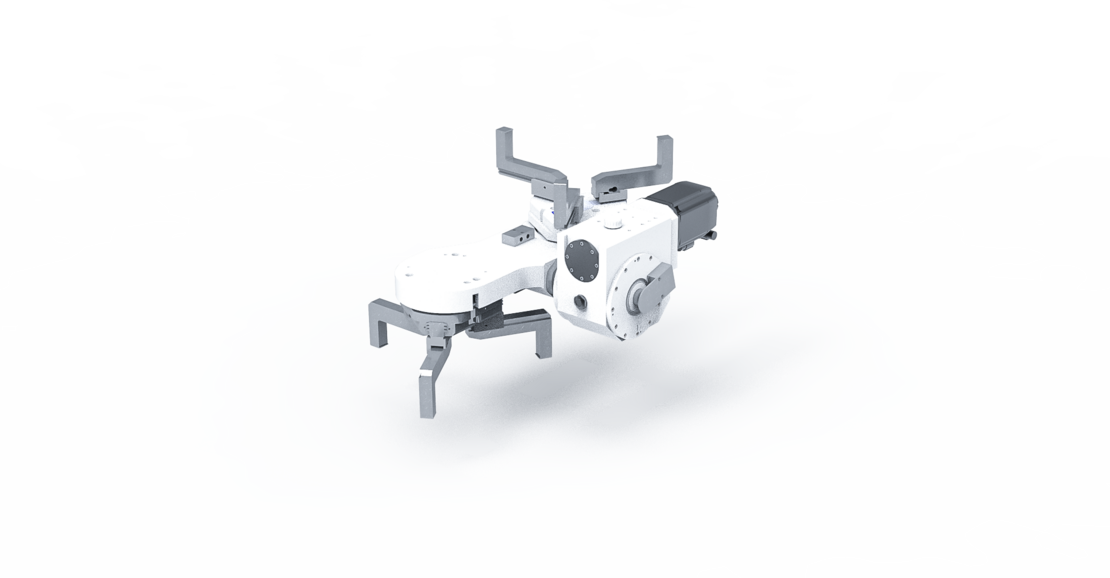

Double centric gripper axially shifted

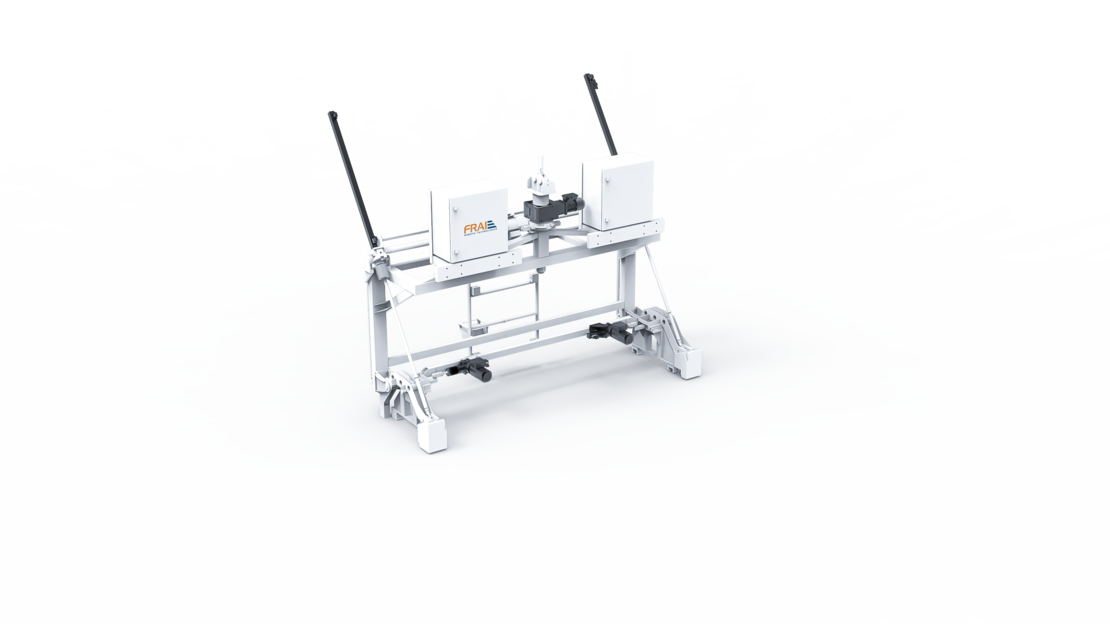

Adjustable gripper yoke with centric gripper

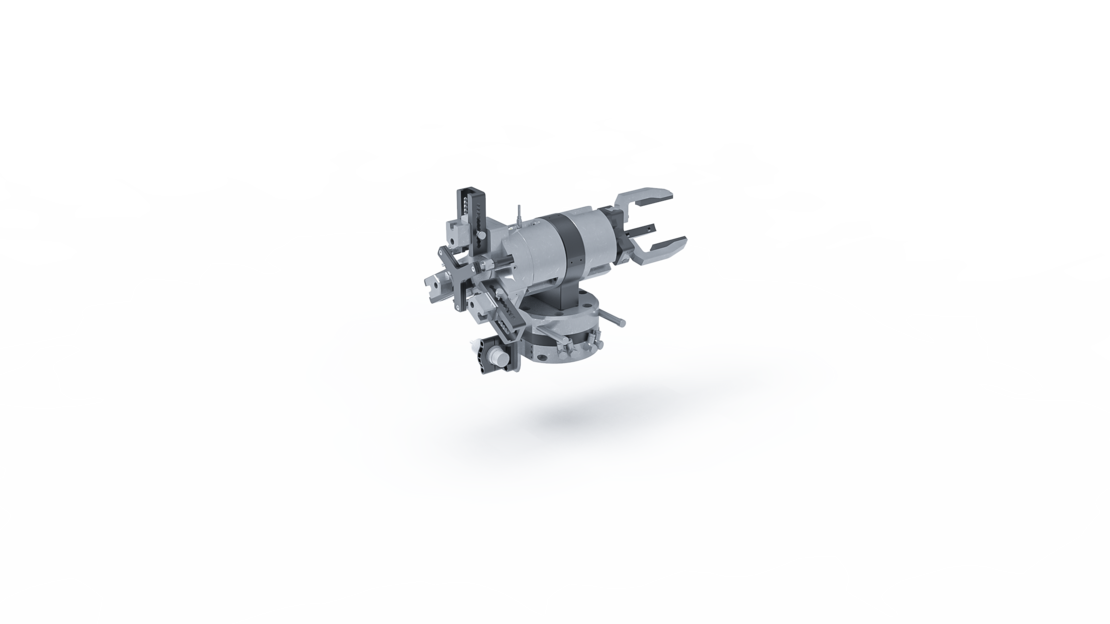

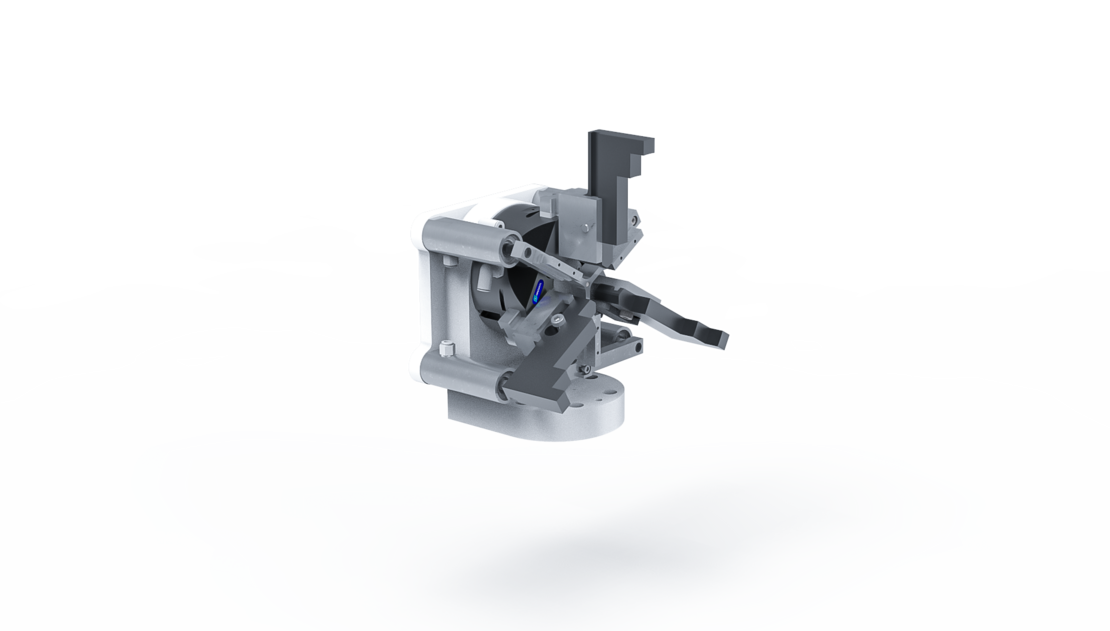

Rotatable and pivotable plate gripper

Double centric gripper

Double centric gripper with tool

Yoke gripper

Pneumatic centric gripper

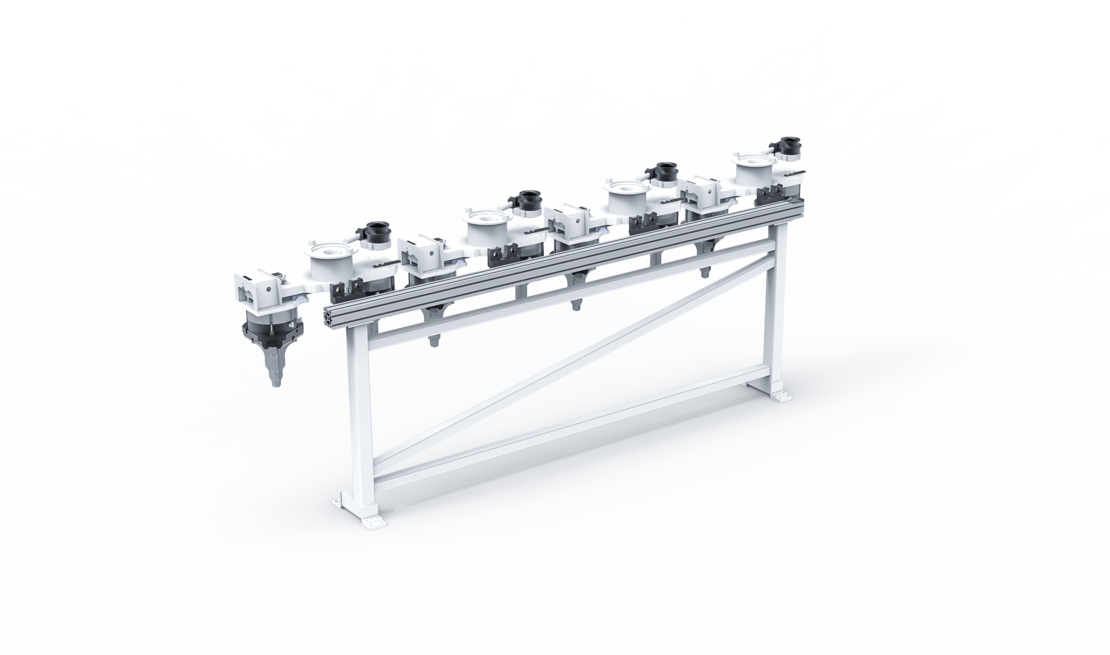

Multiple gripper storage for gripper change

Adjustable gripper yoke with parallel gripper