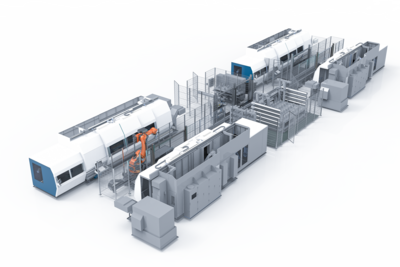

MACHINING LINE

The fastest way to a set up free production thanks to automatic changeover of jaws, tailstock tips and prismatic tools in conjunction with a servomotor gripper for covering an extremely large product range.

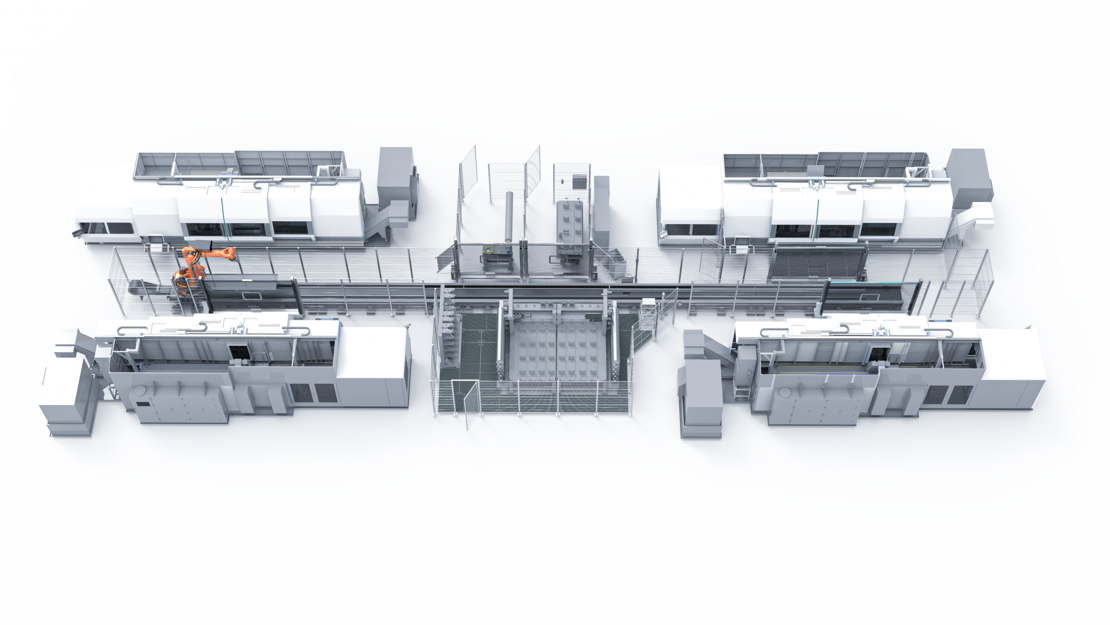

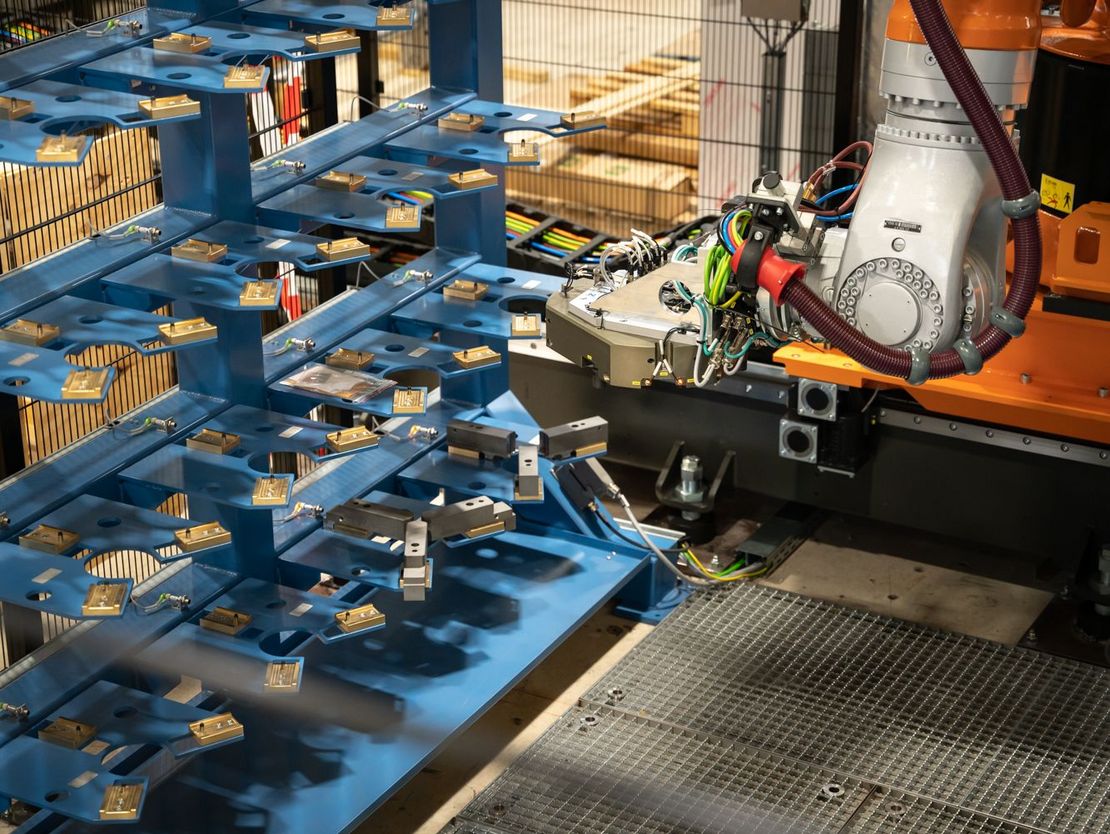

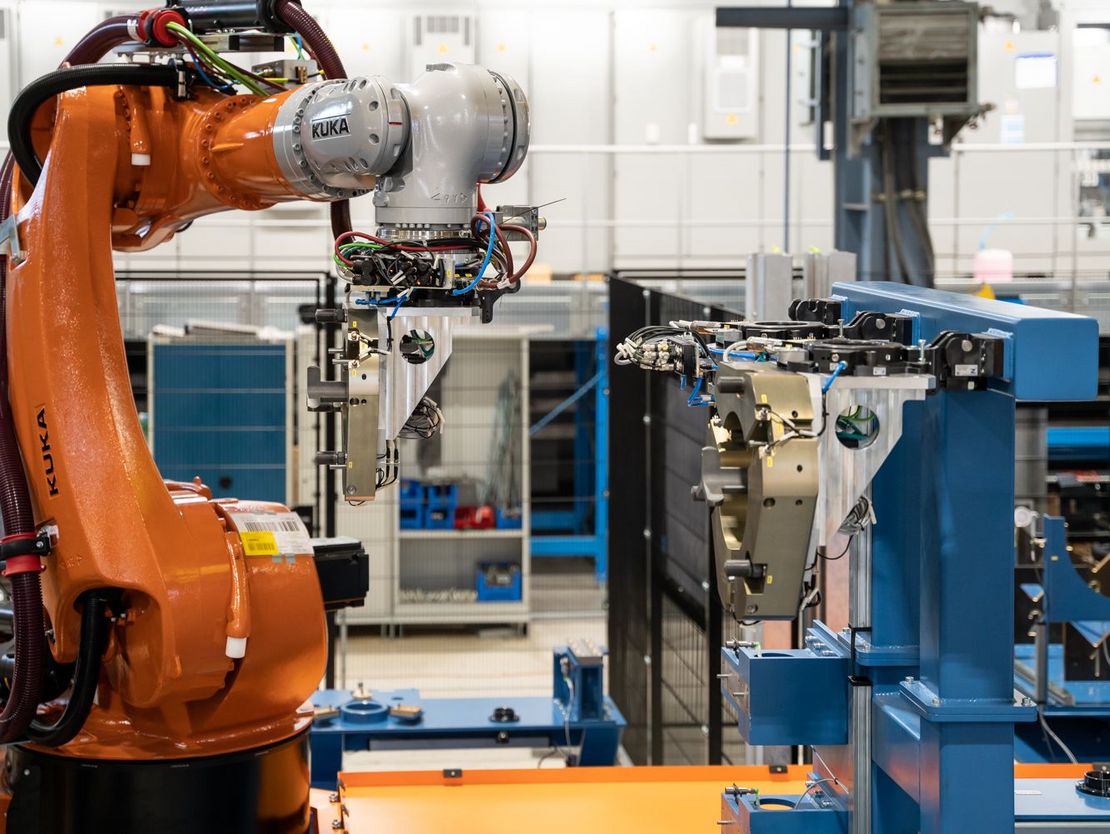

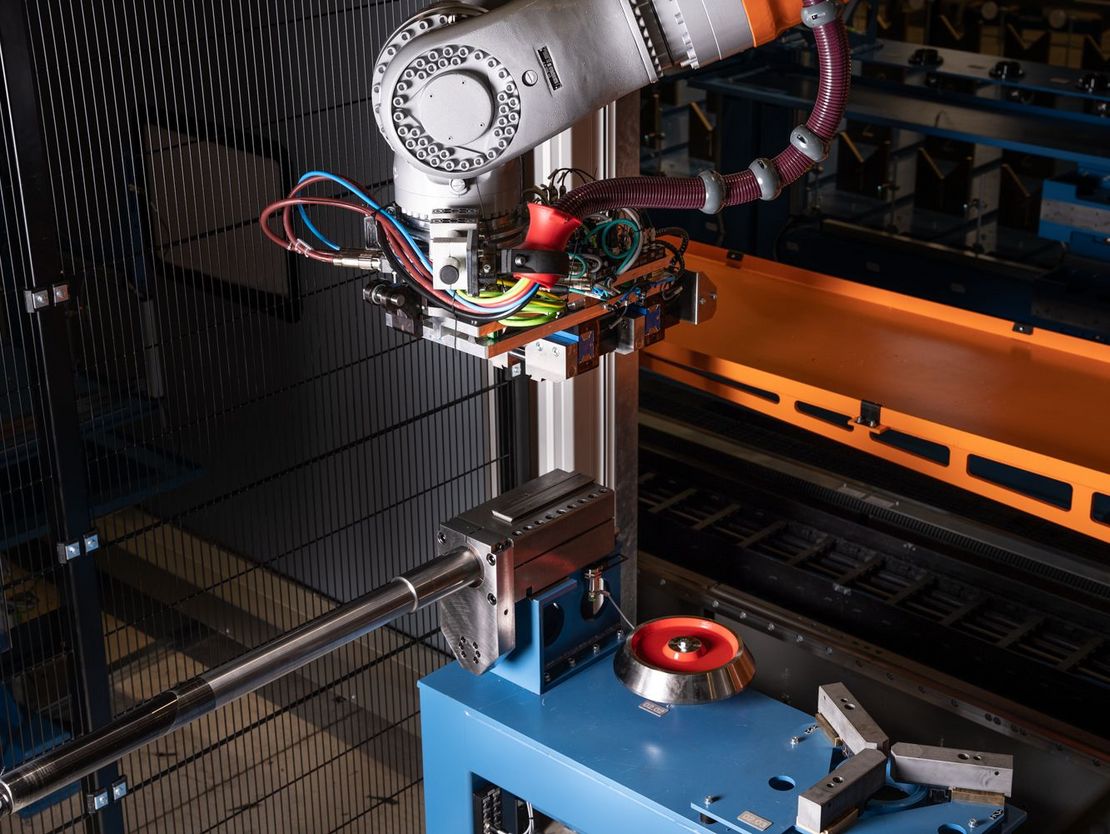

A unique automation project revolves around central automation of four MILLTURN machines. This turnkey system has a whole range of special features. Automatic changeover of jaws, tailstock tips and prismatic tools in conjunction with a servomotor gripper for covering an extremely large product range allows for set-up-free operation of the machines and automation solution. The system features a fully automatic gripper quick-change system and gripper warehouse. Servo grippers for workpieces up to max. 250 kg are used. Grippers for prismatic tools, tailstock tips as well as inner and outer jaws are also used. The 6-axis robot with 480 kg payload is mounted on a 7th axis. A range of grippers can be added to and removed from the production process fully automatically. An integrated drip tray collects coolant and chips.

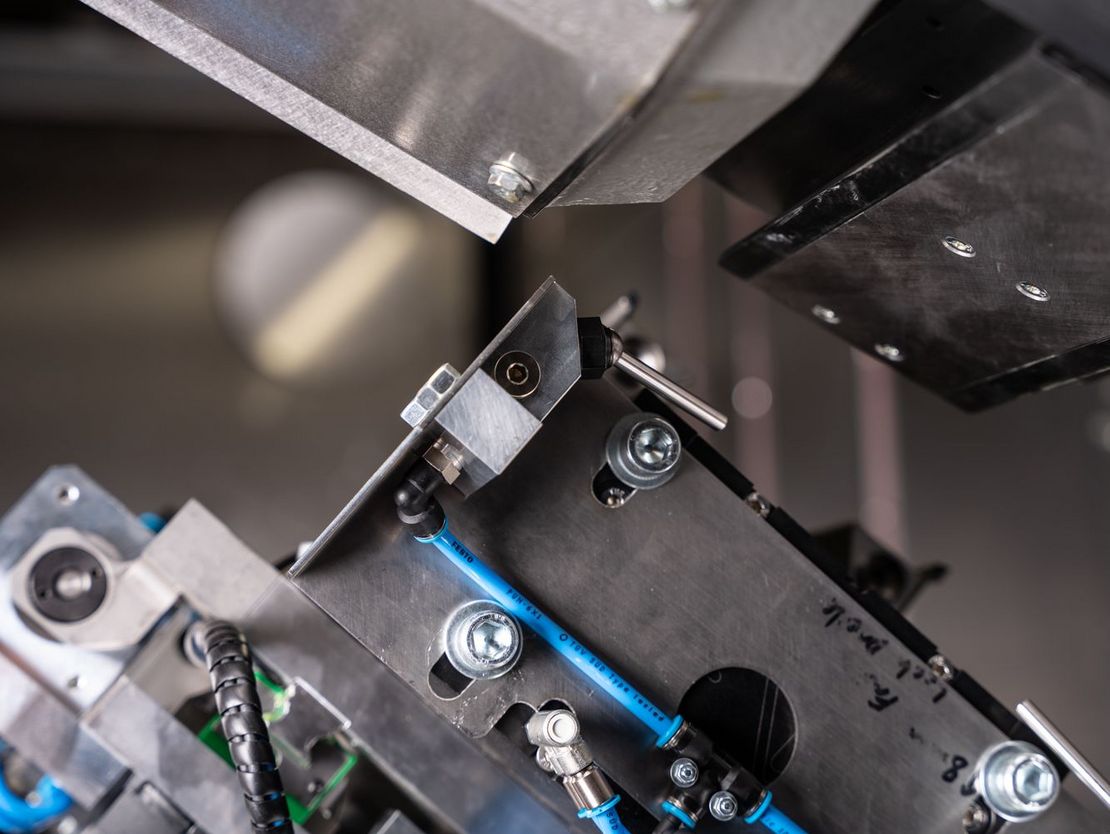

By using two set-up stations for workpieces and tools, tools can be set up and new workpieces can be loaded and unloaded parallel to machining time. The two diameters at which the grippers hold the workpiece are determined via the two servo parallel grippers with an absolute position measuring system. These two values are compared with the nominal diameters stored in the recipe. Two stationary laser light barriers determine the length of the workpieces and compare them with the recipe‘s nominal values. The workpieces‘ offset value from the robot zero point is also calculated.

A special chuck allows for fully automatic jaw change over (simultaneous replacement of the 3-part sets). The tailstock tips can be changed automatically using a special gripper. Another special gripper is able to automatically change the long prismatic tools (up to 2,500 mm long and 250 kg in weight).

Before the new tool is inserted into the machine, the robot moves with the exposed guide to a special station in which the guide is blown off to clean it and then coated with oil. This creates the optimum conditions for a reliable handover process.

Advantages of machine lines at a glance

Set-up free operation

Cost efficient costs per unit

Host computer as "brain"

Switch easily from one workpiece or process to another one